PP woven fabric

PP woven fabric

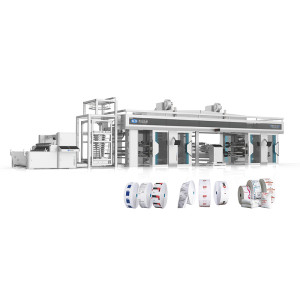

1.The whole machine adopts PLC and frequency conversion drive control system

2.High precision ceramic roller inking system

3. Enclosed chamber doctor blade for scraping ink

4.Thermostatically controlled pressure printing central drum

5.Hd color video inspection, easy to observe the printing quality

6.High precision tension sensor closed loop constant tension design to ensure accurate and stable printing tension

7.High performance rectifying system ensures the linear stability of the base material and the uniformity of the end face of the finished product

8.Independent hot air electric heating and drying unit, high efficiency and energy saving, can also choose heat conduction oil or steam heating

9.Manual registration and pressure control

10.Air pump automatic ink pumping system

1.Stick the plate registration after boot, no need to register, improve the rate of finished products, reduce waste.

2. For the first plate installation, electric positioning fast plate registration system is adopted to complete vertical and horizontal plate registration within 2 minutes.

3. The maximum printing speed can reacstrong50m/min, registration accuracy -0.15mm, overprinting accuracy will not change in the process of lifting.

4. When the machine stops, the material tension is controlled by constant tension, and the material will not run off the offset.

5. The whole machine production line can realize continuous production without shutdown from discharging to finished product rewinding, and maximize production efficiency.

6. The machine has the features of precise structure, easy operation, convenient maintenance and high degree of automation. Only one operation is needed.

|

Model |

KSCI-E-600mm-2200mm |

| Printing color | |

|

Material Width |

600-2200mm |

|

Printing Width |

560-2160mm |

|

Printing Length Range |

345-860mm |

|

Material Diameter |

1200mm |

|

Mechanical speed |

50-220m/min |

|

Printing speed |

50-200m/min |

|

Color Registration precision |

±0.15mm |

|

Color Registration Method |

Automatic |

|

Heating Method |

Electric heating (optional: steam, hot oil, natural gas) |

|

Machine Weight |

Depends On Model |

|

Machine size |

Depends On Model |

|

Working Voltage |

3P 380V |

1.Function: multi-color continuous fine printing, at the same time to achieve reverse gluing

2.Features: accurate color matching, stable operation, model customization

3.Application: mask packaging, pharmaceutical packaging, food packaging

Printing materials:

FFS heavy-duty film, plastic film, woven bag, valve bag, paper plastic bag and other flexible packaging roll materials

1、Main features:

1) The whole machine adopts PLC and frequency conversion drive control system

2)High precision ceramic roller inking system

3)Enclosed chamber doctor blade for scraping ink

4)Thermostatically controlled pressure printing central drum

5)Hd color video inspection, easy to observe the printing quality

6) High precision tension sensor closed loop constant tension design to ensure accurate and stable printing tension

7) High performance rectifying system ensures the linear stability of the base material and the uniformity of the end face of the finished product

Substrate material: BOPP, PVC, PE, PE breathable film, paper, non woven, pp woven sack....